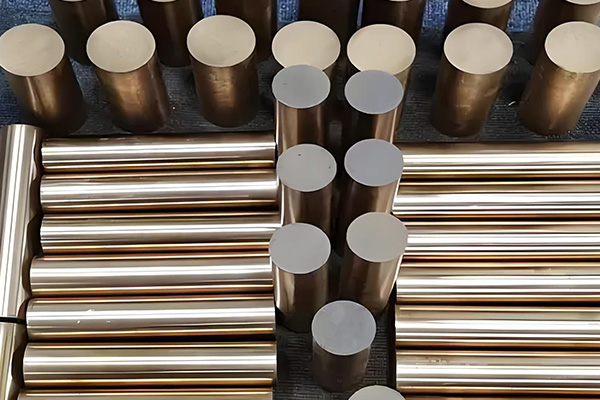

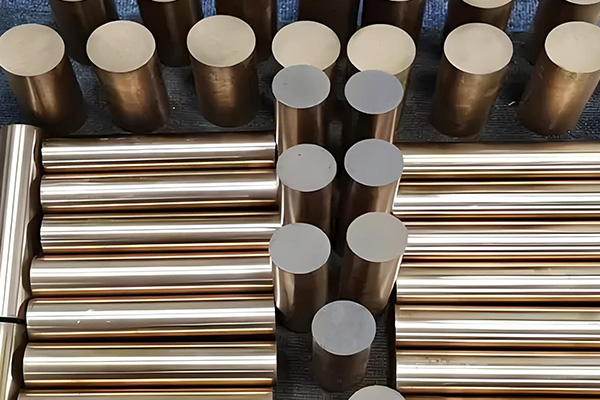

Product Introduction:

Beryllium copper rod is a copper alloy rod based on copper and containing beryllium (Be) as the main alloying element. It has excellent mechanical properties, corrosion resistance, conductivity, and wear resistance, and is widely used in multiple industrial fields.

Product Features:

High strength: It has extremely high strength and hardness, and its strength can be further improved after heat treatment.

Corrosion resistance: It exhibits excellent corrosion resistance in seawater, acidic environments, and atmosphere.

Conductivity and thermal conductivity: Excellent conductivity and thermal conductivity, close to pure copper, suitable for electrical and heat exchange applications.

Wear resistance: It has good wear resistance and is suitable for high friction environments.

Processing performance: Easy to perform cold and hot processing, such as forging, turning, milling, drilling, etc.

Product Application:

Beryllium copper rods are widely used in various fields such as electronics and electrical engineering, automotive industry, aerospace, mechanical manufacturing, mold manufacturing, oil and gas, musical instrument manufacturing, and medical equipment due to their excellent corrosion resistance, high strength, and good electrical and thermal conductivity.

Electronic and electrical industry: used to manufacture electrodes for resistance welding machines, with high conductivity and wear resistance; Used for manufacturing high reliability electrical connectors and switch components; Used for manufacturing spring components with high conductivity and elasticity.

Automotive industry: used to manufacture high-strength parts for automotive engines, such as valve seats, valve guides, etc; A key component used for manufacturing automotive radiators, with good thermal conductivity; Used for manufacturing wear-resistant parts in brake systems.

Aerospace: Key components used in the manufacturing of aircraft and spacecraft, such as bearings, gears, bushings, etc., requiring high strength and corrosion resistance.

Mechanical manufacturing: used for manufacturing high-strength and wear-resistant mechanical parts such as gears, bearings, shaft sleeves, etc.

Mold manufacturing: used for manufacturing high-precision molds with good wear resistance and thermal conductivity.

Oil and gas: used to manufacture downhole tools for oil and gas extraction; Used for manufacturing corrosion-resistant valves and pump components.

FAQ£º

Q1£º Will you deliver on time?

A£º Yes, we promise to provide high-quality products and on-time delivery. Honesty is our company's motto.

Q2: How do you control the quality?

A: Factory testing certification is provided with shipment.

Q3: What are the advantages of the company?

A: We have more professionals, technicians, competitive prices, and excellent after-sales service than other steel companies.